The quality of your final finish is directly dependent on the quality of your surface preparation. A crucial component of that process is the sanding disc. This collection of professional sanding discs is engineered for workshops and enthusiasts who demand efficiency, a consistent finish, and excellent value.

Designed for performance and reliability, our 150mm sanding discs are the ideal choice for a complete range of applications, from aggressive material removal to fine surface finishing.

Our sanding discs deliver:

-

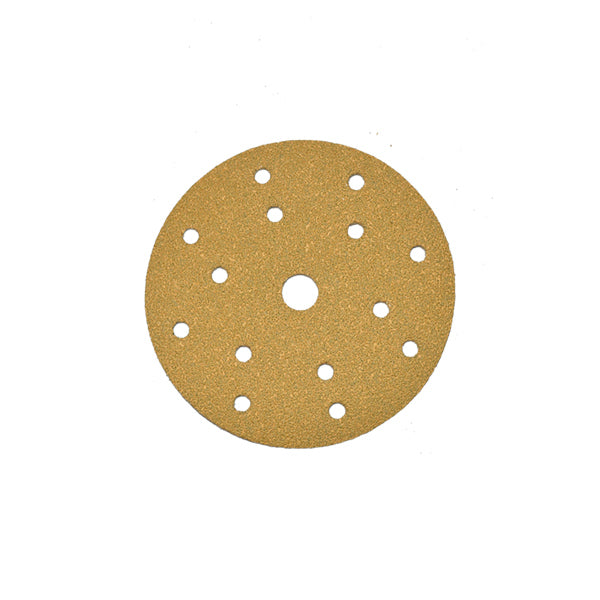

Excellent Performance and a Consistent Cut:

Featuring a durable paper backing and a semi-open coat grain distribution, these discs provide a sharp, reliable cut while resisting clogging. This ensures a uniform scratch pattern for a high-quality finish on primers, fillers, and topcoats. -

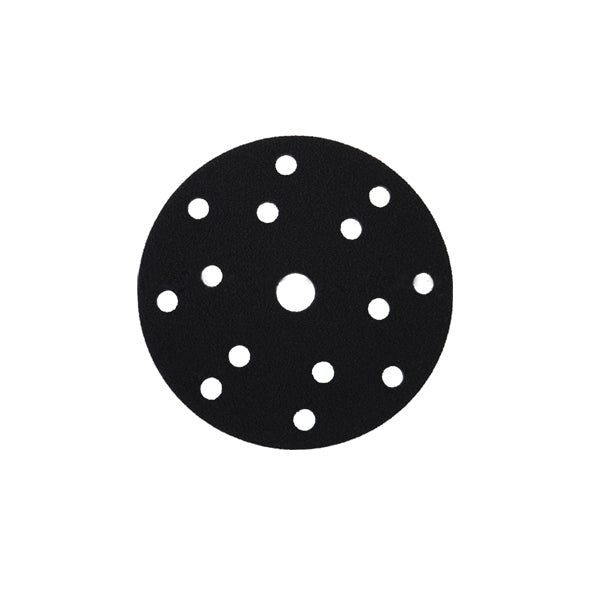

Multi-Hole Pattern for Maximum Dust Extraction:

The 15-hole pattern is designed for superior dust extraction when used with a compatible sander and vacuum system. This keeps the abrasive surface clean, extends the life of the disc, and creates a healthier working environment. -

Durable Hook and Loop System:

Designed for the modern workshop, our sanding discs for DA sanders feature a high-quality hook and loop backing. This allows for quick and easy grit changes on any standard 150mm (6-inch) orbital or dual-action sander, ensuring a secure attachment with no slippage during operation.

The Professional's Choice for Surface Preparation

This collection includes a comprehensive range of grits, from a coarse P40 for rapid stock removal to a fine P120 for finish-sanding primer and fillers. Whether you are sanding automotive body filler, keying panels for a topcoat, finishing raw wood, or prepping metal, these hook and loop sanding discs provide the consistent performance required for a perfect result.

Browse the collection to find the exact grit you need for your project.